Z Pile HR® | Z Pile CF®

Z-Pile HR® | Z-Pile CF®

Z-type sheet piles are the most efficient type of sheet pile in use today. Our Z-Pile systems feature interlocks strategically positioned at a considerable distance from the neutral axis, optimizing shear transmission and enhancing the strength-to-weight ratio. Z-profile sheet pile is predominantly used in retaining walls, floodwalls, parking garages, containment walls, cofferdams, bulkhead walls for ports, and fortifying dams.

Overview

THE Z-PILE:HR® SYSTEM FEATURES an enhanced strength with flexible design.

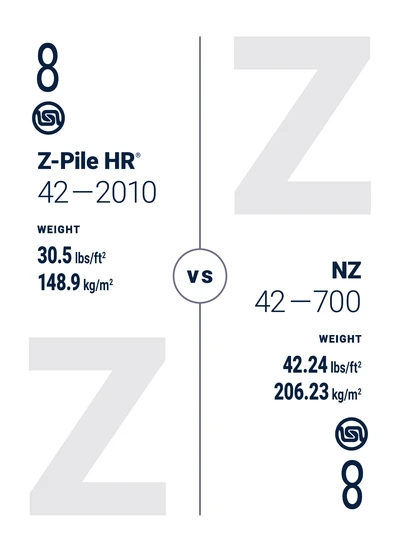

AN INCREASED WIDTH PER PANEL AND LOWER WEIGHT PER SQUARE FOOT OR METER OF WALL COMPARED TO ALTERNATIVE TRADITIONAL Z-SHAPED SHEET PILE DESIGNED TO DRIVEN IN PAIRS.

Our Z-Pile:HR® is hot rolled sheet pile system with interlocks strategically positioned at a considerable distance from the neutral axis. This placement optimizes shear transmission and enhances the strength-to-weight ratio of the system. Z-profile sheet pile is predominantly used in retaining walls and floodwalls, as they are strong enough to help reinforce structures that must withstand constant pressure from one or both sides. They can also be used to create containment barriers for tighter, more specific protection. They are also used in parking garages, containment walls, cofferdams, bulkhead walls for ports, and fortifying dams.

The Z-Pile:HR® sheet pile system features an increased width per panel compared to alternative Z-shaped sheet pile designs. This enhanced geometry results in an efficiency ratio (determined by dividing the section modulus by the weight) that substantially exceeds that of most of not all older Larssen sheet pile sections. Our Z-Pile offerings are available in various configurations to meet your specific requirements, complete with integrated connectors, enabling the construction of diverse geometries in the most efficient manner possible. The Z-Pile:HR® can be installed via a crane and vibration hammer which is same manner most z sheet pile have been installed for decades. Our ability to offer wider and lighter sheet pile configurations translates to quicker, more competitive, and value-driven solutions for our clients.

Key features include:

- Install the same way as a traditional Paired Z - sheet pile such as the AZ 18 or NZ 42

- Flexible design

- Enhanced strength to weight ratio

- Increased width per panel compared to alternative Z-shaped sheet piles, increasing the efficiency ratio

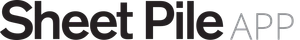

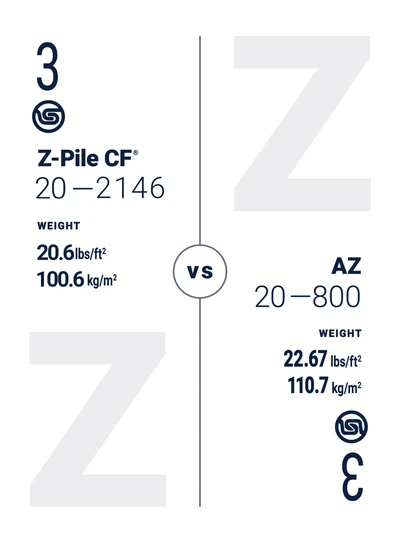

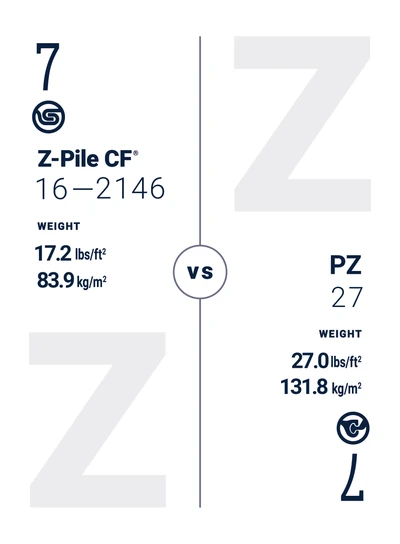

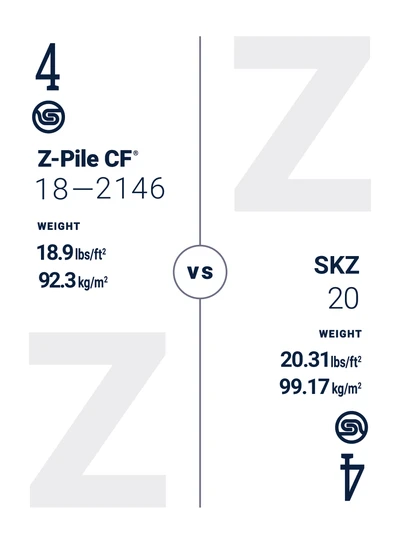

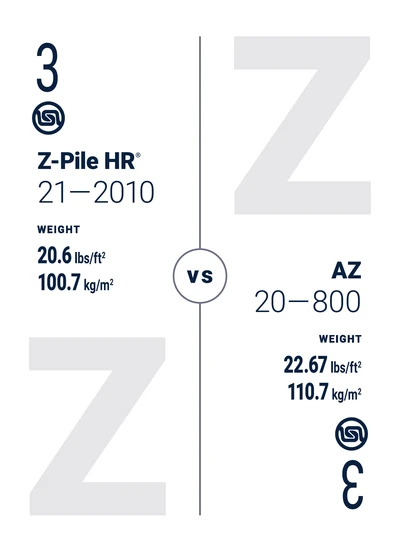

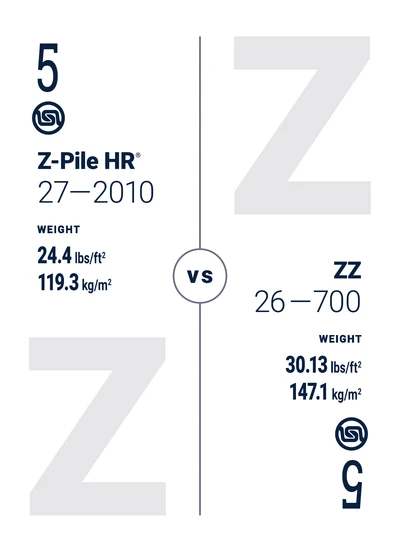

Product Comparisons

Compare our Z-Pile:HR® system with traditional Larssen sheet pile sections.

Videos

Installation

Z-Pile HR® and Z-Pile CF® are typically installed via crane and vibration hammer which is the same manner as most traditional paired Z sheet pile, such as the AZ 18, NZ 42, PZC 18 and ZZ 26. Please let us know about your specific job criteria and we can put you in touch with equipment professionals who can assist you.

Please be aware that should you have significant debris, boulder or facing difficult soil conditions with rock or clay you may want to consider using an O-Pile® DTH system which can be drilled in vertically any soil condition. Please contact us if you are unsure if a Z-Pile HR® would be appropriate given the soil parameters.

Tools

Downloads

Innovative Solutions

Ball and Socket – PZC 18 – Cofferdam

Watertight steel sheet piling cofferdam constructed in California riverbed using WADIT® sealant and PZC-18 sheet piles.

View Details

Chesapeake Bay Bridge & Tunnel

Chesapeake Bay Bridge & Tunnel - O-PILE® INSTALLED THROUGH ROCK JETTY

View Details

East Side Coastal Resiliency Project

HUNDREDS OF O-PILE® SYSTEMS INSTALLED FOR CLIMATE RESILIENCE

View Details

Driving in Difficult Conditions – O-Pile® DTH installed in Rock

First O-Pile® DTH installation in 2010 for the Trondheim road tunnel in Norway, featuring O-Pile® DTH system drilling through quick clay and rock layers for the E6 road project.

View Details

Fukushima Emergency Fortification

Installation of O-Pile® sheet pile system to protect a nuclear power plant and prevent further dam breaches after heavy rains.

View Details

John Hart Dam Steel O-Pile® Cofferdam

Replacement of the existing six-unit, 126 MW generating station in Campbell River, including construction of a new water intake and cofferdam using O-Pile®.

View Details

Katrina and the 17th Street Bridge

Reconstruction of the 17th Street Canal after Hurricane Katrina using PZC sheet pile and PilePro® ball and socket connectors

View Details

Hot Rolled Larssen Sheet Pile

Hot Rolled Larssen sheet pile installation using SUPER CRUSH technology for drainage improvement at Holly Hills in West Hollywood, California.

View Details

O-Pile® Port Construction – Manila North Harbour, Philippines

Manila North Harbour Port container terminal modernization using O-Pile® with X70 pipe and PilePro® connectors, replacing H-sheet pile combined wall systems.

View Details

USACE Tennessee Reservoir - Certified WADIT® Sealant

Critical watertight cofferdam installation in drinking water reservoir using factory-installed WADIT® sealant on ball and socket sheet piles

View Details