Driving Innovation Below Ground.

Overview

Build a better wall, quicker.

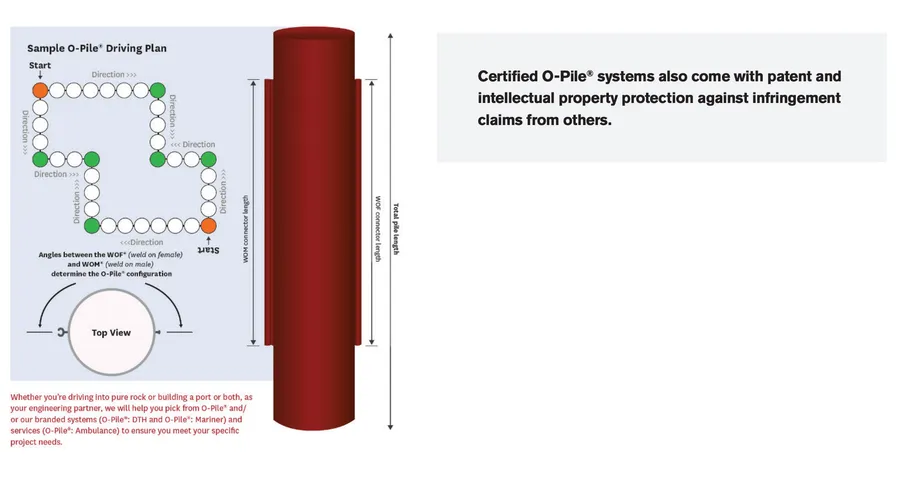

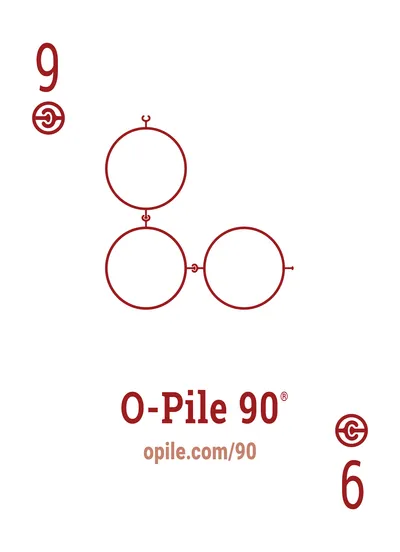

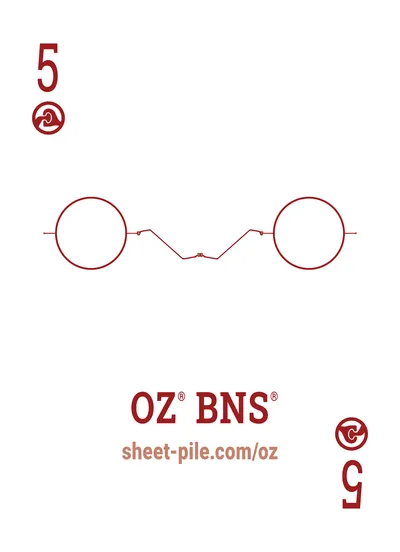

The Certified O-Pile® System is an innovative and rapidly growing construction method that use pipes to create foundations, barriers, and retaining walls. The system uses steel pipes with welded PilePro® connectors to form a continuous pipe sheet pile wall. This approach offers a cost-effective solution with exceptional strength and durability.

O-Pile® systems are a stronger, more efficient, durable, alternative to Z-sheet pile, combined sheet pile utilizing pipes or beams, slurry, secant, continuous concrete walls and other conventional concrete constructions.

The system uses pipe sections with pre-attached connectors allowing one entire section to be driven into the next to form a continuous steel wall with a similar load bearing element. You can drive predictably into pure rock, if necessary, as well as dial-in your corrosion and bending moment needs separately. O-Pile® is versatile and readily available, as you can use your local pipe plant or supplier. Some of the largest sheet pile jobs in North America that are currently being built are specified using the O-Pile® system.

Key features include:

- Faster and more cost-effective alternative to other sheet pile systems and conventional concrete construction

- Can be configured to corrosion-tolerance requirements

- Can be specified by bending moment due to the wide variety of steel grades available

- Can be built from locally available pipes rather than expensive imported steel piles

- Powered by the ball and socket interlock for maximum strength, flexibility, and compatibility

The Certified O-Pile® System

A Certified O-Pile® System guarantees the authenticity and integrity of the O-Pile® plaque. It ensures the components meet the high-quality standards of all Sheet-Pile LLC products and benefit from the expertise and professionalism of the brand's global network of specialists. All certified systems include test reports with an official seal, confirming their authenticity at the time of purchase and ensuring proper functionality. Additionally, you are covered by an international product warranty that guarantees load-bearing capacity, corrosion resistance, and connector interlocking performance.

Ease of Installation

O-Pile® pipe sheet pile system is supported throughout their installation, whereas combined sheet pile systems are not. The installation of the O-Pile® section is similar to driving Z-Pile BNS® in a basic two frame template. At no stage is there an O-Pile® entirely unsupported throughout its length as it is driven to grade. Each section is supported by adjacent section(s) with a small lead ahead of the rest, ensuring accurate wall alignment.

Benefits

Bending Moment Capacity (BMC)

O-Pile® systems typically have a higher strength to weight ratio when compared combined sheet pile walls as they can be made using high strength coiled steel, which exceeds the capabilities of hot rolled sheet pile, and allows for a larger Bending Moment Capacity. For example, O-Pile® is available in X80 to provide 80,000 yield strength, whereas hot rolled sheet piling is limited to less than 65,000 and typically uses steel with a yield strength of 50,000. The selection of the steel grade has a marked impact on the structural resistance of the pile wall. Selecting stronger steel grades such as X70 or X80 often allow for the use of piles with reduced diameters and wall thickness.

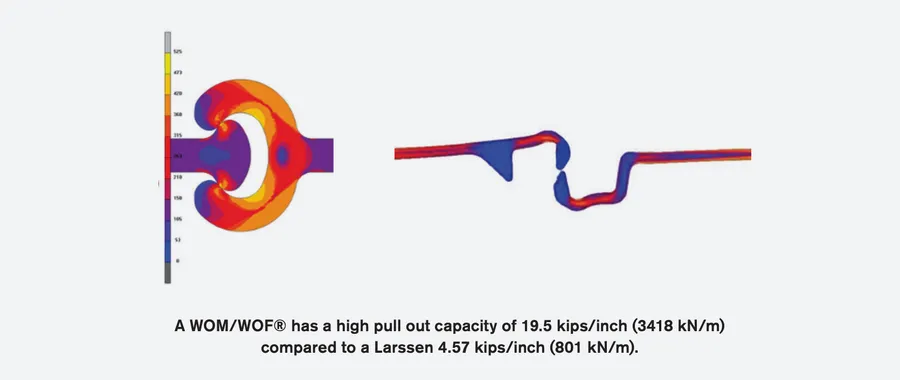

Strong Efficient Connection

PilePro Connectors: WOM (weld on male) and WOF (weld on female) have an interlocking strength of 19.5 kips/inch (3418 kN/m); Figure below shows the high pull-out resistance of the connection, which is more than 4 times stronger than typical Larssen hot rolled sheet pile.

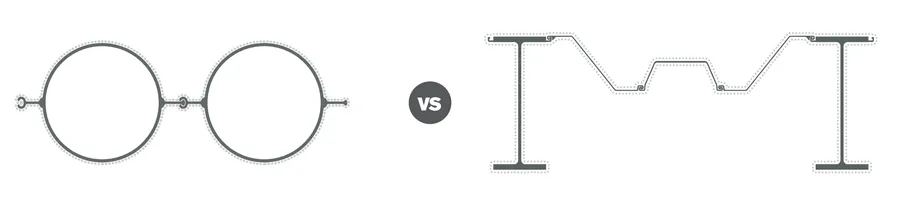

Superior Geometry for Durability

The geometry of O-Pile® results in minimal exposed surfaces, which presents distinct advantages over other sheet pile types. The interior of the pipe can be either capped or filled with concrete to prevent interior corrosion, leaving only the exterior face exposed to potentially corrosive elements. This minimal amount of surface area requiring the application of corrosion protection can result in a notable cost savings. Figure below illustrates the contrasting corrosion exposure between beam king pile and O-Pile®.

Exceptional Strength

O-Pile® systems do not account for the load capacity of the joining connectors, allowing them to be separately calculated for strength, with the full thickness considered sacrificial.

Positional Flexibility

Each WOF/WOM connection provides 20 degrees of rotation to ease placement.

Variable Pipe Thickness

O-Pile® offers adjustable pipe thickness, enabling you to customize each pipe with the thickness needed to match your structural load and durability requirements, all while maintaining optimal safety. The ability to adjust thickness as needed—adding where necessary and reducing where not—ensures the most efficient and cost-effective use of steel. Varying the pipe thickness of O-Pile® targets design life and the use of sacrificial thickness exactly where you need it—in the “Zone of High Attack.” For example, with a 100’ pipe, the thickness of the upper 10’ of pipe (zone of high attack) can be increased to stay well within the corrosion allowance, while the bottom 90’ of the pipe can be dialed-down to meet the load bearing needs. Leveraging O-Pile®’s variable thickness can also eliminate the need for additional coatings, special steel grades, or cathodic protection.

Ease of Installation

O-Pile® pipe sheet pile system is supported throughout their installation, whereas combined sheet pile systems are not. The installation of the O-Pile® section is similar to driving Z-Pile BNS® in a basic two frame template. At no stage is there an O-Pile® entirely unsupported throughout its length as it is driven to grade. Each section is supported by adjacent section(s) with a small lead ahead of the rest, ensuring accurate wall alignment.

O-Pile® paired with WADIT System = Watertight wall

WADIT is the globally proven sheet pile interlock sealant. WADIT (short for WASSERDICHT, German for waterproof) is an environmentally friendly sealant that was developed to deliver robust water-stopping protection. WADIT is available for use anywhere with any type of sheet pile, including O-Pile®. The WADIT system can be utilized before driving sheet pile, in the middle interlock of already paired sheet pile, and after the sheet pile has already been installed. The Certified O-Pile® system is always delivered with WADIT sealant applied in the WOF, serving as a corrosion inhibitor within the connecting elements.

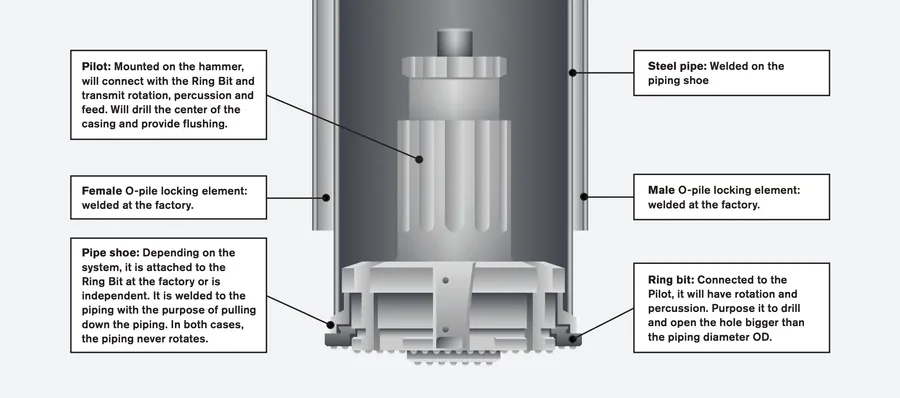

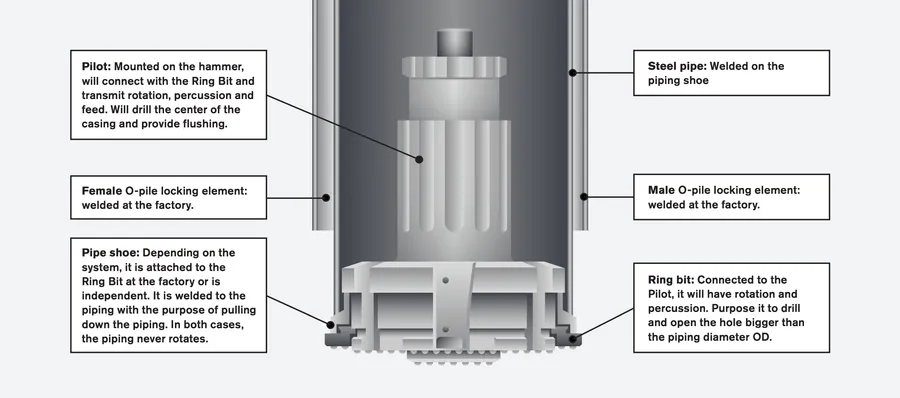

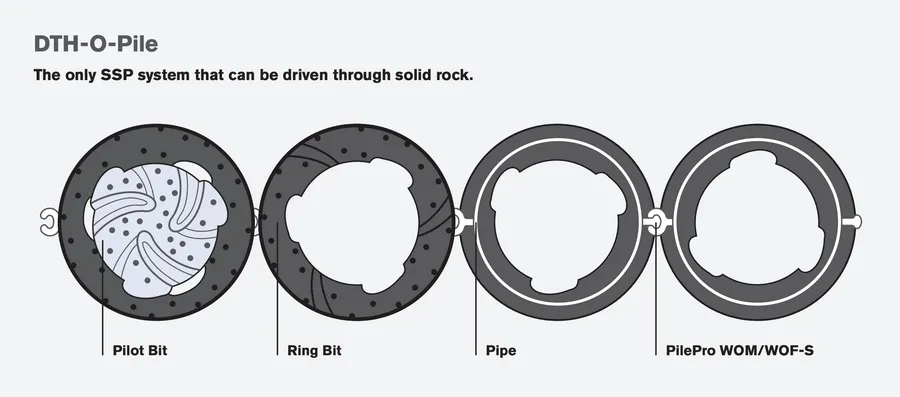

O-Pile®: DTH (Down the Hole) Drilling

A Certified O-Pile®: DTH system pairs the superior quality of O-Pile® with state-of-the-art DTH drilling technology, allowing its systems to be driven into any ground or rock strata at levels of productivity not achieved before. With a Certified O-Pile®: DTH system, predictable and quantifiable installation is possible in difficult driving conditions like bed rock or job sites with heavy debris. The Certified O-Pile®: DTH system is installed with the centric drilling method using ring bits of a larger diameter than standard bits. The ring bit drills a hole larger than the pile to accommodate the WOF/ WOM connectors. Diameter from 10” (323mm) to 42” (914.4mm), ranging from a wide range of diameter pipe can be installed using O-Pile®: DTH. Development of new DTH techniques, especially the introduction of new air control bits, is making DTH drilling safer and more environmentally friendly than ever before. Using DTH in urban areas and in sensitive ground is now possible; plus, there is no danger of overdrilling or air escaping, which could otherwise cause settlement to existing structures. DTH drilling has been used in post glacial soils of Norway, boulders of Sweden, granite of Finland, deep bed rock of Hong Kong, through heavy structure in Macau, and tunnels in Virginia. Every Certified O-Pile® system is delivered with the ring bits attached and ready for use in conjunction with your pilot bit.

Positional Flexibility

Each WOF/WOM connection provides ~20° of rotation to ease placement.

Unmatched Strength

High-capacity O-Pile® systems achieve strength by increasing pipe diameter. This minimizes weight gain per square foot (or square meter) and radically improves strength-to-weight ratio efficiency. Because of its circular geometry the surcharge and lateral load-bearing capacity is significantly higher than standard U- or Z-type sheet pile or combined wall systems of similar weight.

Superior Geometry for Durability

O-Pile® saves costs over combined, Z- and U-sheet pile with easier application of corrosion protection compared to other geometries, and by having a minimized exposed surface: Furthermore, the interior of the pipe can be sealed off (capped or filled) from oxygen infiltration to avoid corrosion on the inside surface. Also, concrete can be poured inside the O-Pile® itself, thus further increasing strength while preventing oxidation or corrosion on the interior surface. This contrasts with a combined sheet pile system, which has all of its surface faces exposed to corrosive elements.

O-Pile®: Double Pipe Thickness

Double pipe thickness allows you to dial-in the specified thickness to meet your specific structural load and durability needs to ensure overall safety. Thickness can be increased specifically at the splash- and low-water zones for increased durability via “sacrificial thickness,” where the sheet pile experiences the greatest corrosive effect. For example, with a spliced 100' pipe, the thickness of the upper 20' of pipe can be engineered for corrosion allowance, while the bottom 80' is specified to meet load-bearing needs.

Tools

Downloads

Videos

O-Pile Installation Process

A step-by-step guide to proper installation techniques for O-Pile systems.

O-Pile DTH (Down the hole)

How it works.

Related Products

Discover other sheet pile solutions that may suit your project requirements.

Schedule Installation

Our expert team is available to help you select the right solution and plan your installation.

Request a ConsultationContent List